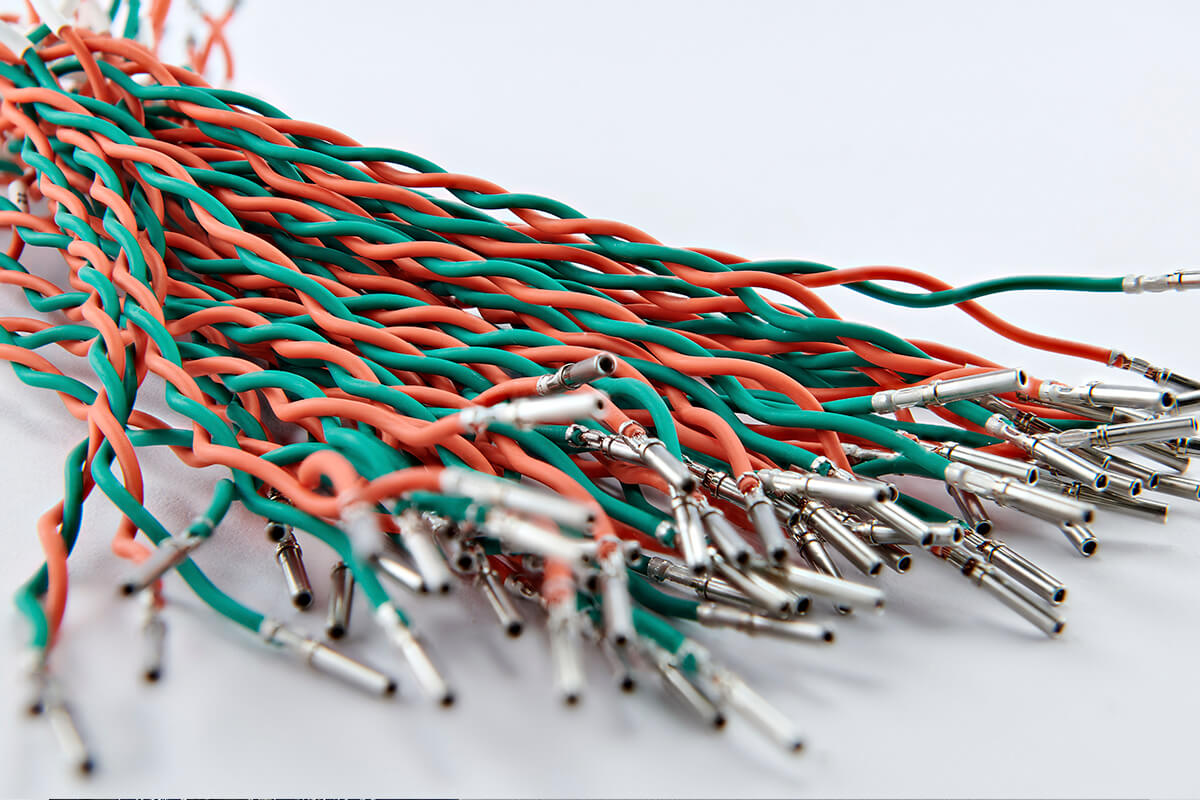

In today’s technologically driven world, seamless connectivity is paramount. While off-the-shelf cables might suffice for simple applications, many industries require specialized solutions to meet their unique demands. Custom cable assemblies provide this tailored connectivity, ensuring optimal performance, reliability, and longevity in critical systems. These assemblies are not merely wires and connectors; they are meticulously engineered components designed for specific environments and functionalities. Let’s explore five key industries where custom cable assemblies play a vital role.

1. Medical Technology: Life-Saving Connections

The medical field demands the highest levels of precision and reliability. Custom cable assemblies are critical in a wide range of medical devices, from diagnostic equipment to surgical tools. These assemblies must be biocompatible, durable, and capable of transmitting sensitive data accurately, often in harsh environments. Consider the following applications:

- Diagnostic Imaging: Connecting sensors in MRI, CT, and X-ray machines.

- Patient Monitoring: Ensuring accurate data transmission from vital signs monitors.

- Surgical Robotics: Enabling precise control and feedback for robotic surgical systems.

- Therapeutic Devices: Powering and controlling devices like pacemakers and defibrillators.

The Importance of Sterilization and Biocompatibility

Medical cable assemblies often undergo rigorous sterilization processes. Therefore, the materials used must be resistant to chemicals and high temperatures. Biocompatibility is also crucial to prevent adverse reactions when cables are used in contact with patients.

2. Aerospace and Defense: Mission-Critical Performance

In aerospace and defense applications, failure is not an option. Custom cable assemblies are essential for aircraft, spacecraft, and military equipment, where they must withstand extreme temperatures, vibrations, and electromagnetic interference. These assemblies are designed for exceptional durability and reliability, ensuring uninterrupted operation in demanding conditions. Examples include:

- Avionics Systems: Connecting flight control systems, navigation equipment, and communication systems.

- Military Vehicles: Powering and controlling communication, surveillance, and weapons systems.

- Satellite Communication: Transmitting and receiving data in space.

3. Industrial Automation: Keeping Production Running Smoothly

Industrial automation relies heavily on sophisticated control systems and robotics. Custom cable assemblies are used to connect sensors, actuators, and controllers, ensuring precise and efficient operation of manufacturing processes. These assemblies often need to be ruggedized to withstand harsh industrial environments, including exposure to chemicals, dust, and extreme temperatures.

4. Telecommunications: The Backbone of Communication

The telecommunications industry relies on high-speed, reliable data transmission; Custom cable assemblies are vital for connecting network equipment, transmitting signals, and ensuring seamless communication across vast distances. These assemblies must meet stringent performance standards to maintain signal integrity and minimize data loss. This includes applications like:

- Data Centers: Connecting servers, switches, and storage devices.

- Cellular Networks: Connecting base stations and antennas.

- Fiber Optic Networks: Transmitting data at high speeds over long distances.

5. Automotive Industry: Powering the Future of Transportation

The automotive industry is undergoing a rapid transformation, with the increasing integration of electronics and advanced driver-assistance systems (ADAS). Custom cable assemblies are crucial for connecting sensors, control units, and infotainment systems, enabling features like autonomous driving, electric vehicle charging, and advanced safety systems. These cables have to withstand harsh conditions like extreme temperatures, vibrations, and exposure to corrosive fluids.

These five industries represent only a fraction of the applications where custom cable assemblies are essential. The ability to tailor these components to specific needs ensures optimal performance, reliability, and safety across a wide range of critical systems. As technology continues to evolve, the demand for custom cable assemblies will only continue to grow. They are the unsung heroes of modern technology, quietly powering innovation and enabling countless applications that we rely on every day. Their custom-engineered design is a testament to the need for specialized solutions. Finally, custom cable assemblies are essential for industries seeking optimal performance and reliability.