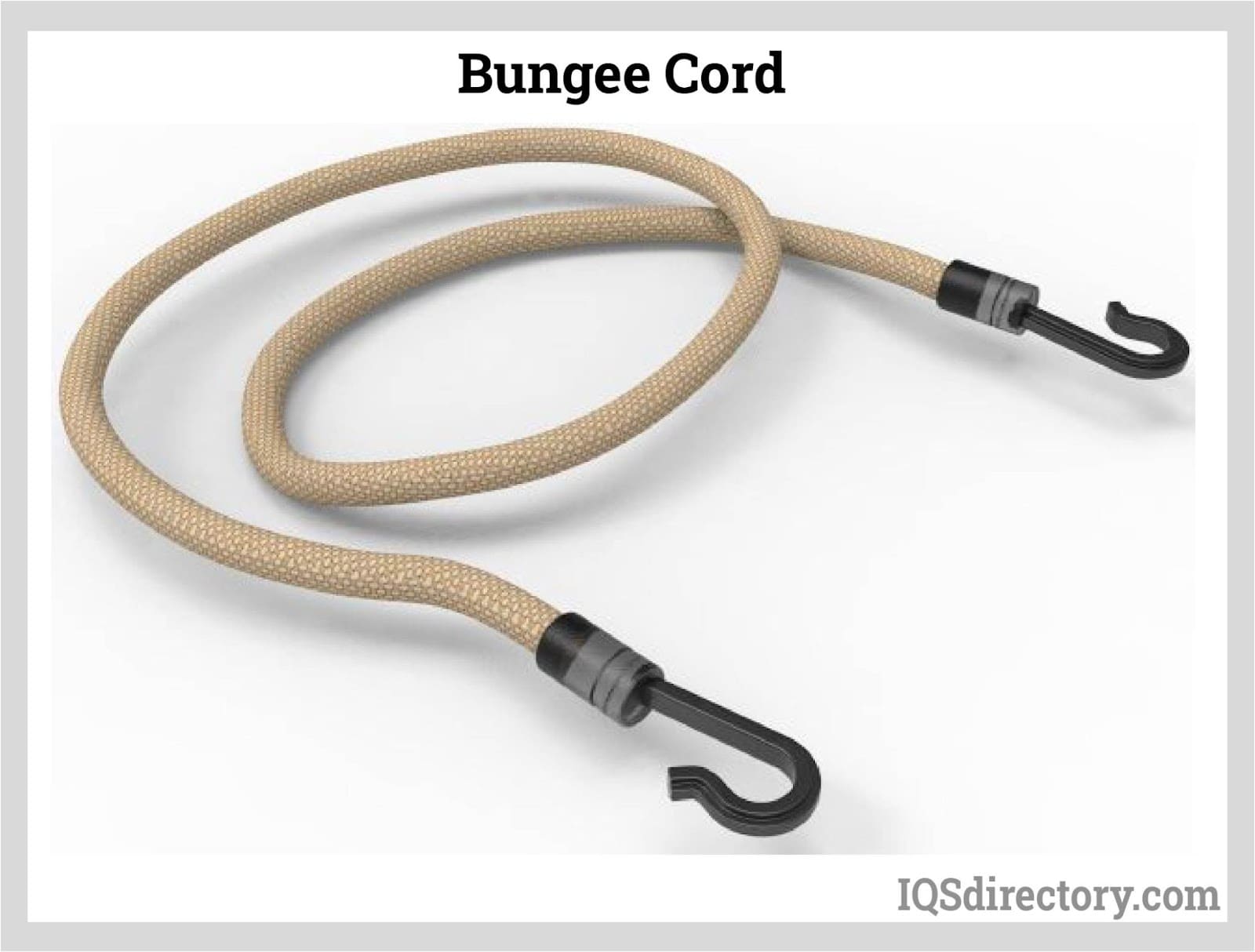

Bungee jumping is an adrenaline-pumping activity that relies heavily on the quality and composition of the bungee cord. The elasticity and strength of the cord are paramount for a safe and exhilarating experience. Understanding what materials are used and how they contribute to the cord’s performance is crucial. The construction of a bungee cord is more complex than it appears, involving several key components working in harmony. Let’s delve into the fascinating world of bungee cord materials and their significance.

The Core Elastic Material: Latex Rubber Strands

The heart of a bungee cord lies in its elastic core, typically constructed from numerous strands of high-quality latex rubber. These strands are responsible for providing the primary elasticity and rebound force necessary for the jump. The more strands used, the greater the overall strength and elasticity of the cord. Different bungee jumping operations may use cords with varying numbers of strands based on the jumper’s weight and the desired jump characteristics. The quality of the latex rubber is also critical, as inferior materials can degrade quickly, compromising safety.

Protective Sheathing: Ensuring Durability and Longevity

The latex rubber core is vulnerable to damage from UV radiation, abrasion, and other environmental factors. Therefore, it’s encased in a protective sheathing, usually made from woven nylon or polypropylene. This sheathing significantly extends the lifespan of the bungee cord. It also provides additional strength and helps to distribute the load evenly across the elastic core. The color and weave pattern of the sheathing can also indicate the cord’s capacity and intended use. This sheathing isn’t just aesthetic; it’s a vital safety component.

Nylon vs. Polypropylene Sheathing: A Quick Comparison

| Feature | Nylon Sheathing | Polypropylene Sheathing |

|---|---|---|

| Strength | Higher tensile strength | Good tensile strength |

| Abrasion Resistance | Excellent | Good |

| UV Resistance | Moderate | Good |

| Water Absorption | Absorbs water | Water-resistant |

| Cost | Generally more expensive | Generally less expensive |

Reinforced End Loops: Secure Attachment Points

The end loops of a bungee cord are critical attachment points that connect the cord to the jumper’s harness and the anchor point. These loops are heavily reinforced to withstand immense stress during the jump. Typically, multiple layers of durable webbing, such as nylon or polyester, are used to create these reinforced loops. Furthermore, they are often stitched with high-strength thread in a reinforced pattern to prevent tearing or failure. Regular inspection of these loops is crucial for safety.

Safety Considerations: Inspection and Maintenance of Bungee Cords

Even with high-quality materials, bungee cords are subject to wear and tear. Regular inspections are vital to identify any signs of damage or degradation. Operators should check for:

- Frays or cuts in the sheathing

- Exposed or damaged elastic strands

- Weakened or damaged end loops

- Discoloration or signs of UV damage

Proper storage and maintenance are also essential to prolong the life of the bungee cord. This includes:

- Storing cords in a cool, dry place away from direct sunlight.

- Cleaning cords regularly with mild soap and water.

- Avoiding exposure to harsh chemicals or solvents.

- Following the manufacturer’s recommendations for lifespan and replacement.

FAQ About Bungee Cord Materials

What happens if the bungee cord breaks?

Bungee cords are designed with multiple layers of redundancy and undergo rigorous testing. However, failure can occur. Reputable bungee jumping operations have comprehensive safety protocols in place, including backup systems and trained personnel to handle emergencies.

How often should bungee cords be replaced?

The lifespan of a bungee cord depends on several factors, including the frequency of use, environmental conditions, and the quality of the materials. Manufacturers typically provide guidelines for replacement, and operators should adhere to these recommendations strictly. Frequent inspection is a must regardless of age.

Are there different types of bungee cords for different weights?

Yes, bungee cords are available in various strengths and lengths to accommodate different weights and jump heights. Operators carefully select the appropriate cord based on the jumper’s weight to ensure a safe and controlled jump.

Can I make my own bungee cord?

No. Manufacturing a safe and reliable bungee cord requires specialized knowledge, equipment, and materials. Attempting to make your own cord is extremely dangerous and should never be attempted. Always rely on professionally manufactured and inspected cords.

The composition of a bungee jumping cord is a carefully engineered blend of elasticity, strength, and durability. From the core latex rubber strands to the protective nylon sheathing and reinforced end loops, each component plays a vital role in ensuring a safe and exhilarating experience. Rigorous testing, regular inspections, and proper maintenance are crucial for maintaining the integrity of the cord. Understanding the materials used in bungee cord construction helps to appreciate the level of engineering and safety considerations involved. Remember, the thrill of bungee jumping comes with the responsibility of prioritizing safety above all else. By understanding the cord’s components, we can better appreciate the science and engineering behind this exhilarating sport.