Unlocking Billions: Why Mastering Net Weight Vs. Gross Weight is Your Supply Chain’s Secret Weapon!

In the intricate tapestry of global commerce, where every gram and every dollar counts, a fundamental distinction often overlooked holds the key to immense savings, unparalleled efficiency, and robust regulatory compliance. We are talking about the critical difference between Net Weight Vs. Gross Weight – a concept far more profound than simple arithmetic. As of today, September 18, 2025, industries worldwide are increasingly recognizing that a granular understanding of these measurements isn’t merely a logistical detail; it’s a strategic imperative shaping everything from freight costs to consumer trust.

Imagine the vast oceans traversed by colossal cargo ships, the endless highways humming with delivery trucks, and the bustling warehouses where goods are meticulously prepared for their journey. Each stage of this complex ballet is governed by weight. The nuances separating net weight, gross weight, and tare weight fundamentally dictate shipping costs, influence vehicle load limits, and are inextricably linked to safety regulations. By integrating insights from precision weighing, businesses are not just moving products; they are orchestrating a symphony of optimized operations, unlocking unprecedented levels of cost-effectiveness and operational agility across their entire supply chain. This distinction, often buried in shipping manifests, is truly the bedrock of modern logistics.

| Key Weight Term | Definition | Primary Application & Significance |

|---|---|---|

| Net Weight | The actual weight of the product or cargo itself, excluding any packaging, containers, or transport materials. | Crucial for pricing, freight classification, inventory management, and consumer labeling (e.g., food products). Represents the true quantity of goods. |

| Gross Weight | The total weight of the product or cargo, including all its packaging, containers, and any other materials used for containment or transport. | Directly impacts shipping costs, vehicle load limits, safety regulations, and customs declarations. It’s the ‘all-inclusive’ weight for transport. |

| Tare Weight | The weight of an empty container, packaging, or vehicle without any goods loaded. | Essential for calculating net weight (Gross Weight ⏤ Tare Weight = Net Weight) and ensuring compliance with vehicle weight restrictions. |

| For more detailed information on shipping and logistics best practices, visit Inecta Blog: Gross Vs. Net Weight | ||

The Weighty Distinction: Unpacking the Definitions

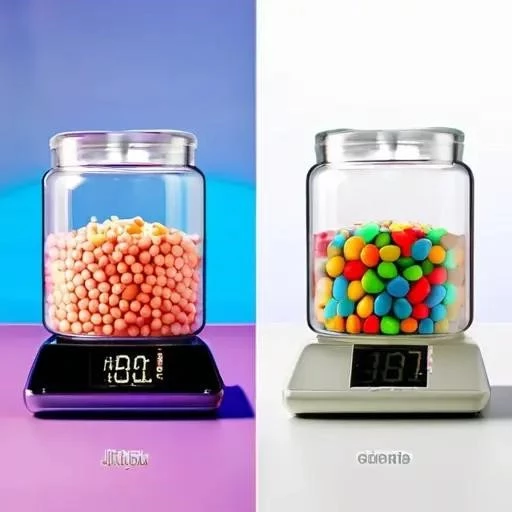

Let’s delve deeper into these foundational terms. Net weight, in its purest form, represents the unadulterated mass of the product. If you’ve ordered a beautifully crafted dresser, its net weight is the 50 kgs of the furniture itself, devoid of any encumbrance. This figure is paramount for manufacturers tracking raw material usage and for consumers assessing the actual quantity of goods purchased. It’s the core value, the substance without the shell, influencing pricing and freight classification.

Conversely, gross weight encompasses the entirety. Taking our dresser example, if it arrives boxed up with additional wood pallets for support and protective Styrofoam packaging, the total weight might swell to 60 kgs. This 60 kgs is the gross weight. It includes the product, its immediate packaging, and any supplementary materials essential for safe transit. Carriers universally base freight charges on this gross figure, as it accounts for every single component being transported, directly impacting fuel consumption, vehicle wear, and overall logistics planning.

Industry Impacts: A Ripple Effect Across Sectors

The implications of accurately distinguishing between these weights resonate across a multitude of industries, acting as a silent yet powerful determinant of success:

- Shipping and Logistics: Here, gross weight is king. It dictates the type of vehicle required, the maximum load capacity, and, critically, the shipping costs. Miscalculating gross weight can lead to costly delays, fines for exceeding legal limits, or even safety hazards. By meticulously tracking these figures, logistics giants are streamlining operations, ensuring optimal container utilization, and bolstering profit margins.

- Manufacturing and Production: Net weight is the bedrock for manufacturers. It informs inventory control, material procurement, and production planning. Understanding the precise net weight of components ensures product consistency and minimizes waste, driving efficiency and sustainability in production lines.

- Consumer Goods and Retail: For the everyday shopper, net weight is a testament to transparency and fair trade. Regulatory bodies mandate clear net weight declarations on packaging, empowering consumers to make informed purchasing decisions and compare product values accurately. This builds invaluable trust and safeguards against deceptive practices.

- Food Industry: Perhaps nowhere is net weight more critical than in the food sector. Beyond regulatory compliance for labeling, it directly impacts nutrition information, portion control, and food safety. A bag of rice, for instance, must accurately reflect its 5 kg net weight, ensuring consumers receive precisely what they expect and facilitating precise dietary planning.

Calculating Clarity: Simple Formulas, Profound Results

The calculations themselves are refreshingly straightforward, yet their accurate application yields profoundly impactful results:

Gross Weight Calculation:

Gross Weight = Net Weight + Weight of Packaging and Materials

This formula encapsulates everything that will be moved, from the product to its protective layers.

Net Weight Calculation:

Net Weight = Gross Weight ⏤ Weight of Packaging and Materials

This provides the pure weight of the commodity, stripped of its transport accoutrements.

Consider a shipping container holding 100 units, each weighing 2 kg. If the collective packaging, pallets, and other transport materials add another 50 kg, the calculation becomes clear. The net weight of the product is 200 kg (100 units * 2 kg). However, the gross weight, the figure that truly matters for transport, surges to 250 kg (200 kg + 50 kg). This distinction, when applied consistently, prevents costly misjudgments and ensures smooth operational flow.

Navigating the Challenges: Precision in a Dynamic World

While the concepts are clear, achieving absolute precision in weight measurement presents its own set of challenges. Variability in packaging materials, the complexities of accurately determining tare weight for irregularly shaped containers, and dynamic environmental conditions (like temperature affecting liquid weights) all demand meticulous attention. Furthermore, the accuracy of weighing equipment itself is paramount; regular calibration and maintenance are not optional but essential investments in operational integrity.

The Future is Weight-Optimized: An Optimistic Outlook

Looking ahead, the mastery of Net Weight Vs. Gross Weight is not just about avoiding penalties; it’s about pioneering new frontiers of efficiency and sustainability. By leveraging advanced IoT sensors, AI-driven analytics, and sophisticated supply chain software, companies are moving beyond reactive compliance to proactive optimization. This forward-looking approach allows for real-time weight monitoring, predictive analytics for load balancing, and even dynamic packaging adjustments to minimize gross weight without compromising product safety.

This era of intelligent logistics, driven by precise weight data, promises a future where waste is minimized, costs are dramatically reduced, and supply chains operate with unprecedented fluidity. Businesses that embrace this nuanced understanding of weight are not merely adapting; they are actively shaping a more efficient, transparent, and profitable global trade landscape. The journey towards a truly optimized supply chain begins with a clear understanding of every gram, every kilogram, and the profound difference between what’s inside and what’s included. The future of commerce is undoubtedly lighter, smarter, and infinitely more precise.