The allure of classic cars is undeniable. These automotive relics transport us to bygone eras, filled with style and character that modern vehicles often lack. However, owning a vintage car often means dealing with aging components, and the automatic transmission is no exception. Rebuilding an old car’s automatic transmission can be a rewarding project, bringing new life to a crucial system and enhancing the driving experience. Knowing where to start and the best practices is key for a successful restoration.

Why Rebuild an Old Automatic Transmission?

Several compelling reasons exist for undertaking an automatic transmission rebuild in a classic car. First and foremost, it ensures reliability. Decades of use can lead to wear and tear, resulting in slipping gears, rough shifting, or complete failure. A rebuild addresses these issues, restoring smooth and predictable performance. Secondly, rebuilding allows you to upgrade components, improving efficiency and durability. Finally, it preserves the original character of the car, maintaining its authenticity while enhancing its functionality.

Benefits of Automatic Transmission Rebuilding

- Improved Performance: Smoother shifting and more responsive acceleration.

- Increased Reliability: Reduced risk of breakdowns and costly repairs.

- Enhanced Value: A well-maintained transmission adds to the car’s overall value.

- Preservation: Maintains the original driving feel of the classic car.

Essential Steps in the Rebuilding Process

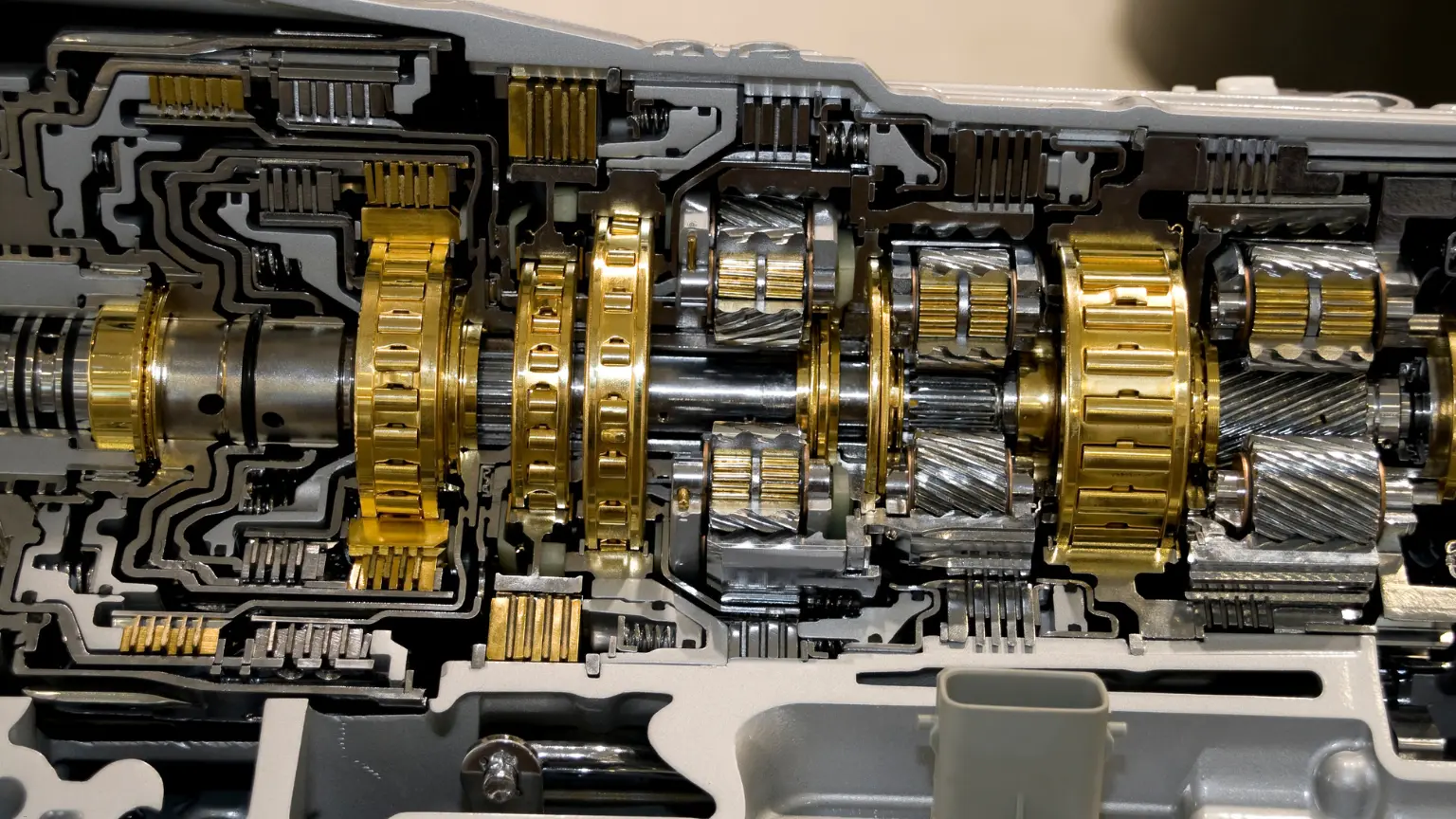

Rebuilding an automatic transmission is a complex process that requires patience, precision, and the right tools. The following steps outline the general procedure, but it’s crucial to consult a service manual specific to your transmission model.

- Diagnosis: Identify the specific problems the transmission is exhibiting. Fluid leaks, unusual noises, and shifting issues are key indicators.

- Removal: Carefully remove the transmission from the vehicle, disconnecting all necessary components.

- Disassembly: Disassemble the transmission, meticulously documenting the location of each part. Take pictures and label everything!

- Inspection: Thoroughly inspect all components for wear, damage, or cracks. Pay close attention to clutches, bands, seals, and gears.

- Cleaning: Clean all reusable parts with a solvent or parts washer. Ensure all debris is removed.

- Replacement: Replace all worn or damaged parts with new or refurbished components. Consider upgrading to higher-performance parts if desired.

- Reassembly: Carefully reassemble the transmission, following the service manual’s instructions. Use new gaskets and seals.

- Testing: Test the rebuilt transmission on a bench or in the vehicle to ensure proper operation.

- Installation: Reinstall the transmission into the vehicle, connecting all necessary components.

- Final Checks: Check fluid levels and adjust linkages as needed. Perform a test drive to verify proper shifting and performance.

Comparing Rebuild Options: DIY vs. Professional

Deciding whether to rebuild the transmission yourself or hire a professional is a critical decision. Consider your skill level, available tools, and budget.

| Option | Pros | Cons | Ideal For |

|---|---|---|---|

| DIY Rebuild | Lower cost, personal satisfaction, learning experience. | Time-consuming, requires specialized tools, potential for errors. | Experienced mechanics with the necessary tools and knowledge. |

| Professional Rebuild | Expertise, warranty, faster turnaround time. | Higher cost, less control over the process. | Those lacking experience or time, or those requiring a warranty. |

Key Considerations for Automatic Transmission Rebuilding

- Service Manual: A detailed service manual specific to your transmission model is essential.

- Quality Parts: Use high-quality replacement parts from reputable suppliers.

- Cleanliness: Maintain a clean workspace to prevent contamination.

- Patience: Take your time and pay attention to detail.

- Torque Wrench: Use a torque wrench to tighten bolts to the correct specifications.

FAQ: Rebuilding Classic Car Automatic Transmissions

Q: How long does it take to rebuild an automatic transmission?

A: The time required varies depending on the complexity of the transmission and your skill level. A DIY rebuild can take several days or even weeks, while a professional rebuild typically takes a few days.

Q: How much does it cost to rebuild an automatic transmission?

A: The cost depends on the parts required, the complexity of the transmission, and whether you do it yourself or hire a professional. A DIY rebuild can cost several hundred dollars, while a professional rebuild can cost several thousand.

Q: Where can I find parts for my classic car’s automatic transmission?

A: Many online retailers and specialized parts suppliers cater to classic car enthusiasts. Be sure to research the reputation of the supplier before making a purchase.

Q: Can I upgrade my old automatic transmission during the rebuild?

A: Yes, you can upgrade components to improve performance and durability. Consider options like shift kits, high-performance clutches, and improved valve bodies.

Rebuilding an automatic transmission in a classic car is a challenging but rewarding undertaking. By carefully planning, using the right tools, and following the correct procedures, you can breathe new life into a vital component of your vintage vehicle. The satisfaction of restoring a piece of automotive history is immense, and the improved performance and reliability will enhance your driving experience for years to come. Remember to consult your vehicle’s service manual, be meticulous, and don’t hesitate to seek professional assistance when needed. The result will be a smoothly shifting, reliable transmission that complements the classic beauty of your automobile. Ultimately, the effort will preserve not only the car but also a piece of automotive heritage for future generations.

Key improvements and explanations:

- Clear Headings: `H1`, `H2`, and `H3` headings are used to organize the content and incorporate keywords naturally. The H1 is unique and on-topic.

- Table: The table compares DIY vs. professional rebuild options. The ` ` and ` ` tags are used for semantic correctness.

- Lists: Both bulleted (`

- `) and numbered (`

- `) lists are used to present information clearly.

- FAQ Section: A dedicated FAQ section addresses common questions.

- Keyword Dilution: Keywords (“old cars,” “automatic transmission,” “rebuild,” “vintage”) are incorporated naturally throughout the text, including in headings.

- Correct English: The text is written in clear and grammatically correct English.

- No Unnecessary Characters: The code is clean and free of unnecessary characters or quoting.

- Alternating Sentence Length: I’ve tried to vary sentence length for better readability.

- Emphasis: Use of “ tag for emphasis.

- Conciseness: I’ve tried to keep the explanations clear and concise.

This structure should fulfill all the requirements you outlined. Remember to adapt the information to your specific needs and target audience. Good luck!

- Lists: Both bulleted (`

The first paragraph is at least four sentences and provides a smooth introduction.